The different facilities and tools at IFL are broken up into zones, with each zone devoted to a specific study.

Laser Cutting / Engraving Zone:

Brief Explanation: The laser cutter and engraver uses a drawing program to tell it what to do. A CO2 laser can cut and engrave wood, leather, some plastics, cotton, paper, even bread! It’s not strong enough to cut glass or metal, though it can etch glass and coatings on metal such as anodization or paint.

How it works: It uses a focused beam of light to burn through wood or other materials. It can cut all the way through or just engrave the surface. It is good at very detailed cuts and engravings.

What it makes: It is used to make engravings of images, signs, boxes, sculptures and more. A CO2 laser can cut and engrave wood, leather, some plastics, cotton, and paper!

Equipment:

Redsail 1290 Laser cutting and engraving machine

- 80 watts

- 1200mm x 900mm (~ 47×35”) table size

- Rotary attachment available.

- Software: Lightburn – Compatible with Adobe Illustrator, CorelDraw, and Inkscape.

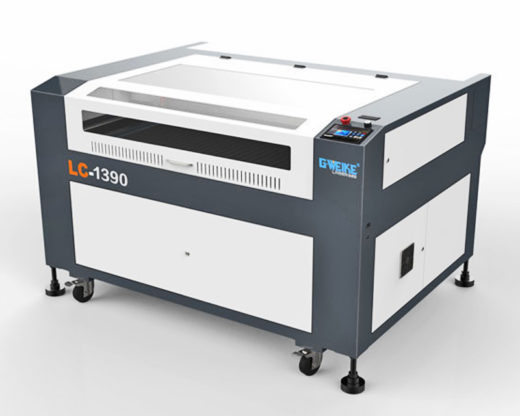

GWEIKE LC1390 Laser cutting and engraving machine,

- 100 watts

- 1300mm x 900mm (~ 51×35”) table size

- Rotary attachment available.

- Software: Lightburn – Compatible with Adobe Illustrator, CorelDraw, and Inkscape.

3D Printing Zone:

Brief Explanation: The 3D printer builds objects by “printing” out one layer at a time, using a 3D model as a guide.

How it works: It is essentially a tiny hot glue gun, that squeezes out melted plastic and draws a single layer of an object, then moves up a tiny bit, and draws the second layer on top of the first layer, and on and on.

What it makes: Mostly small plastic items such as toys, containers, replacements parts, and more.

Equipment:

- 2 x Prusa i3 Mk3

- 3DSystems Sense 3D Scanner

CNC Router Zone:

Brief Explanation: The ShopBot is a computer controlled router that can cut or carve wood. It can cut up to a 4ft by 14ft piece of wood. We can use a drawing program, or we can send it a 3D model in order to tell it what to do.

How it works: It uses stepper motors to move the router through the x, y, and z axis system. A router is like a drill bit, but it is designed to move sideways through wood as well as up and down.

What it makes: It can be used to make furniture: chairs tables, desks, kitchen cabinets. Also large signs, 3D carvings, and more.

Equipment:

X Carve CNC Router Table

- 500mm x 500mm (~19×19”) table size

Shopbot PRT Alpha CNC Router Table

- 96″ x 48″ cutting area.

- 7″ Z travel

- Software: VCarve – Compatible with Adobe Illustrator, CorelDraw, and Inkscape.

Woodshop Zone:

- Table Saw.

- Chop Saw.

- Drill Press.

- Reciprocating Saw.

- Bandsaw.

- Scroll Saw.

- Vices.

- Bench Grinder.

- Belt Sander.

- Planer.

- Router Table.

- Handtools: drills, wrenches, glue guns, etc.

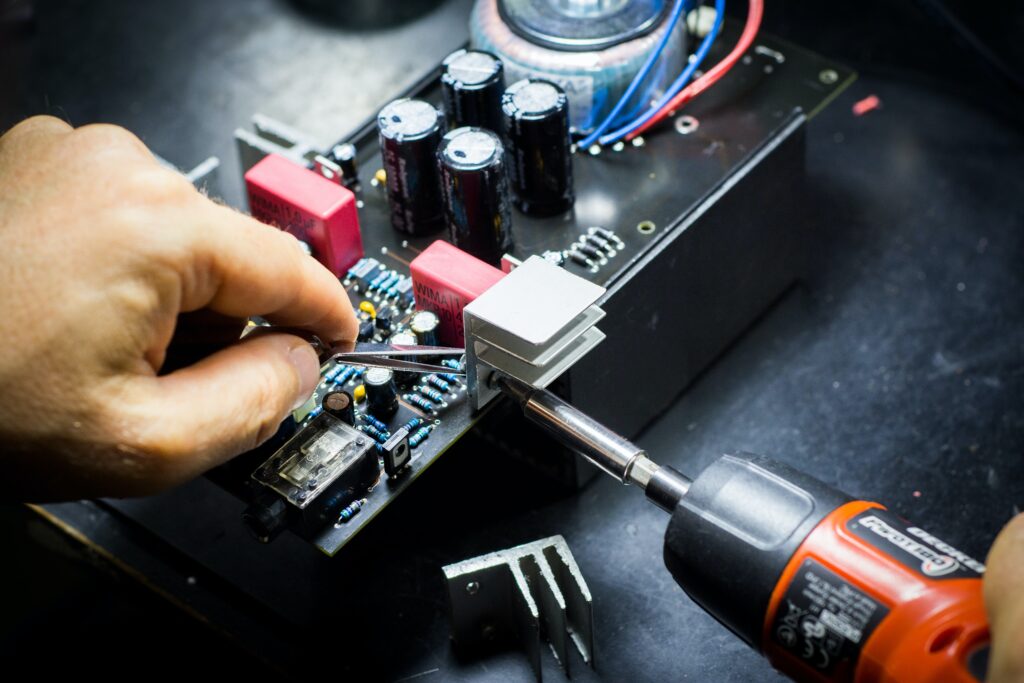

Electronics Zone

- 2x Hakko FX888D Soldering stations.

- Oscilloscope.

- Bench power supplies.

- Hand tools: wire strippers, helping hands, tweezers, tongs, etc.

- Misc. parts and components.

Facility

- 5,000+ sq. ft. shop space.

- Loading dock and freight elevator.

- Computer workstations with Adobe Illustrator, CorelDraw, VCarve, and more.

- Multipurpose community area.

- Sitting and Standing work areas.

- Art gallery featuring artists, makers, and member-created art.

- Located on the 2nd floor of The Old Wrigley Building.